CNC Milling: What is it, How It Works

By definition, CNC stands for Computer Numerical Control. A computer numerical control (CNC) machine is a tool that can be programmed to do its job over and over again without human intervention. This means not only can automatic machines run unattended, but they can also produce very complex parts in large volumes.

What is CNC milling and what are its applications?

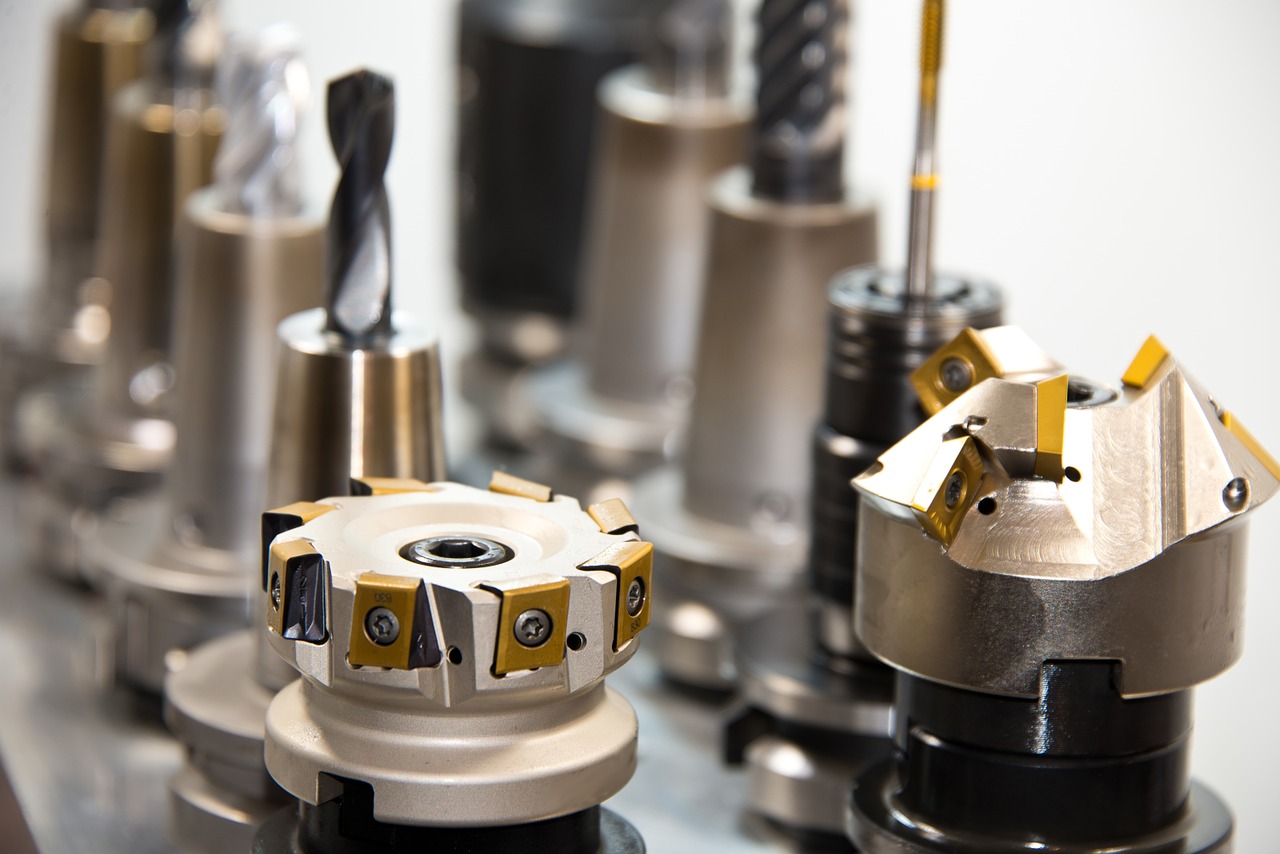

CNC milling is a manufacturing process in which material is cut away by a rotating cutting tool, like a drill bit. With CNC Milling, it’s possible to create complex and intricate parts that couldn’t be otherwise produced by the traditional method of casting or stamping.

Examples of applications for CNC milling

CNC milling is used everywhere, from small businesses to large corporations. In fact, CNC milling is one of the most widely used manufacturing processes in industry today. Some job shops can have hundreds or even thousands of machine tools specifically for CNC Milling purposes.

How does a CNC mill work? – the basics

A CNC mill uses a series of linear axes and rotary axes just like a 3D printer does. The difference between the two is that the cutter on a CNC mill doesn’t move in any direction, it’s always rotating around its axis. A cutting tool attached to this rotating shaft is moved closer and closer to the material, which is held stationary, and cuts away the material. This is called subtractive manufacturing because one layer of material is reduced to reveal the next.

The different types of CNC mills

You can categorize CNC mills into two types, based on the motion of the cutter relative to the workpiece.

The first type is called a horizontal machining center (HMC) and it has one axis for moving the tool vertically or horizontally across the material. This means that all three-dimensional features must be carved into the surface before the HMC can make any cuts.

The second type is called a vertical machining center (VMC) and it has an additional rotating axis, which means the tool can make a pass along a surface to remove material while also making a cut from the side. This makes VMCs more efficient because they don’t have to carve out three-dimensional features first, but they still have to do a finishing pass from the back of the material.

For milling, as for turning and other processes, the CNC machine has a spindle with a cutter held rigidly in place by bearings and often additionally supported by a chip auger or some other means so it can remove material more efficiently.

How to choose the right CNC mill for your needs

CNC milling machines are offered with a range of work envelopes.

For example, you’ll need to look at the size of the smallest workpiece your machine can hold in order to determine if it’s small enough for your needs. Other factors include ease of use, reliability, power and overall capabilities compared to other CNC machines.

How much does it cost?

CNC milling machines range from $1,000 to as much as $100,000, depending on what you need them for and how big they are. There can also be additional expenses, such as tooling and software.

What’s the bottom line? If you’re just getting into machining, a small manual milling machine, or a bench top milling machine, can be a good investment. If you’re looking to do large-scale projects, such as airplane wings and engine parts, you’ll need something larger and more expensive.

Tips on using and maintaining a CNC mill

For safety purposes, always wear goggles and ear protection when using a CNC milling machine. Keep your hands away from the cutting area, or use cut-off gloves if you need to adjust something on the spindle.

When lining up pieces for work, make sure that they are secure and at right angles to each other so there is no risk of them slipping while you cut. After cutting a piece, make sure to turn the milling machine off before removing it.

Keeping the machine in good condition will ensure that it functions properly. After every hour of use, clean the machine, oil all moving parts and make sure bolts are secure.

Conclusion

A CNC mill can change your life if you’re into boatbuilding or hobbyist woodworking, and they are invaluable tools for prototyping and design work in industrial settings. Used correctly, they can pay for themselves in a short time.

Thanks for reading!