There are various electronic products which people are using on a daily basis for fulfilling the requirements of their lives such as for having a convenient life, for sharing and providing information to each other and for inspiring creativities as well. That is why the electronic industry has grown out as one of the most productive industries of the world and is still rising as the technology is also developing at a much faster rate.

It has even been assumed that the electronic sector is further going to evolve better in future which no other sector has developed at such rate. By having a rapidly evolving nature, it has become very crucial for the industry to adopt the highest quality manufacturing process. And to ensure these standards, various electronic industry marking solutions are there which can certainly create a better future.

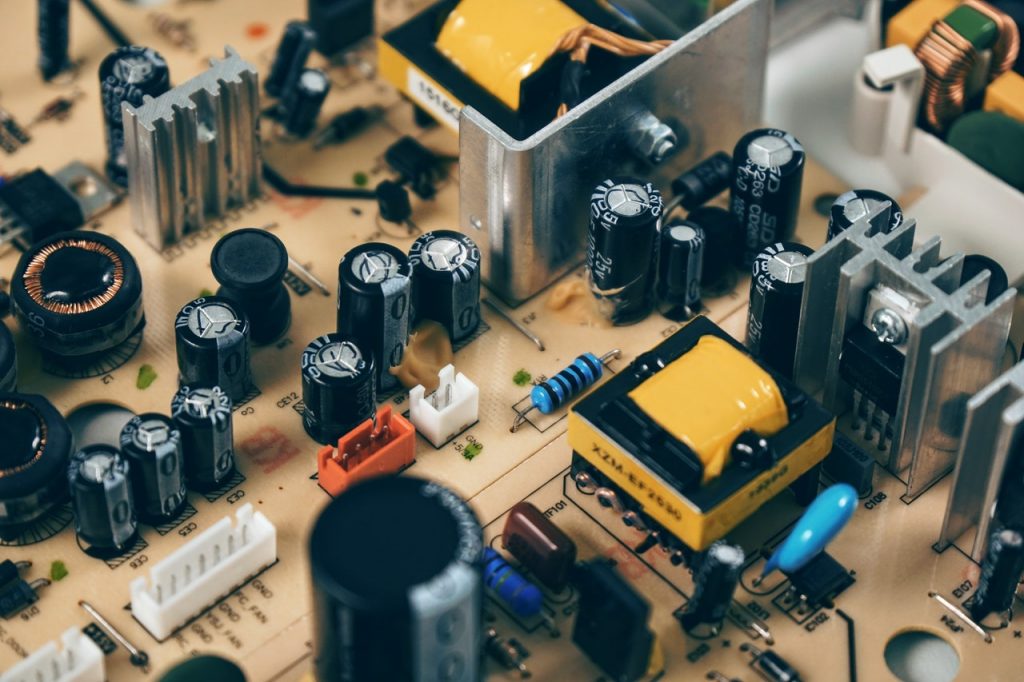

Marking On Electronic Equipment Parts:

The number of electronic devices such as smartphones, tablets etc are growing rapidly which increases its number of users as well as sales. The increasing demand of these electronic equipment further leads to the production of these devices which certainly demands its producers to carefully implement the traceability control standards. By following the prescribed standards eventually ensures the great quality of these electronic products.

Earlier the manufacturers were using the conventional marking machines for directly marking on the electronic devices but technology has changed so many things in the world and so in the electronics industry as well. Now they have switched to the laser marking machines for marking on the electronic products which provides a fine, less damaging and high quality marking directly on the product. Further, there is no more requirement of direct contact of the person with the device as only need to set up the laser marking machine which performs accurate operation.

Here let’s take a quick look at various technologies used for Electronic Industry Marking Solutions below:

- Micromarking:

Many production sectors need to have some written information on the product so it also requires to have the written information on the electronic products as well. Now when it’s the matter of marking on electronic devices then the space is very limited here but the required information is crucial. So, smaller text sizes are required to be adopted for marking on the electronic devices.

And for this purpose, the technique of micromarketing is used. This technique is used with the help of laser marking machines that provides ultra fine marking on electronic devices which is otherwise impossible with the conventional marking machines. Now when the laser marking machine is used for the electronic industry marking then here you have the benefit of using different styles conveniently as per your electronic device. This process certainly produces very less damage to your devices where deep engraving literally involves the maximum height contrast into the device parts.

- 2D Code Marking on Device Chips:

In various electronic components, the IC chips are being used in these devices. On these IC chips, the lot numbers need to be marked in the form of 2D code marking which were considered as highly typical in conventional marking systems. Further these lot numbers are too small in size for which Laser Marking Machines are used that are capable enough to mark the smaller text as required without damaging the device parts.

Electronic Device Marking on LED Ceramic package:

As we have already talked about the limited space on these electronic devices, but here with the increasing demand of electronic equipment in the market, various marking standards have been laid down which every producer of this industry certainly requires to follow. Thus to follow and implement the proper industrial marking solutions, the demand for the 2D codes on the ceramic package of the electronic device as well has also been increased. This is because these ceramic packages contain all the necessary information regarding the particular electronic device on which they have been installed.

Conclusion:

Here in this content, we have provided you with various Electronic Industry Marking Solutions which are going to bring a major change in the growth of technology and electronic components as well. The electronic industry has grown at the fastest rate and the size of the industry is getting bigger and bigger. So, to provide better working standards for this electronic industry, the upgraded electronic device parts marking solutions will be required in future where some of them we have already mentioned here.