MicroHarvest Scales Microbial Protein Production to 10 Tons Per Day, Paving the Way for Full-Scale Facility by 2026

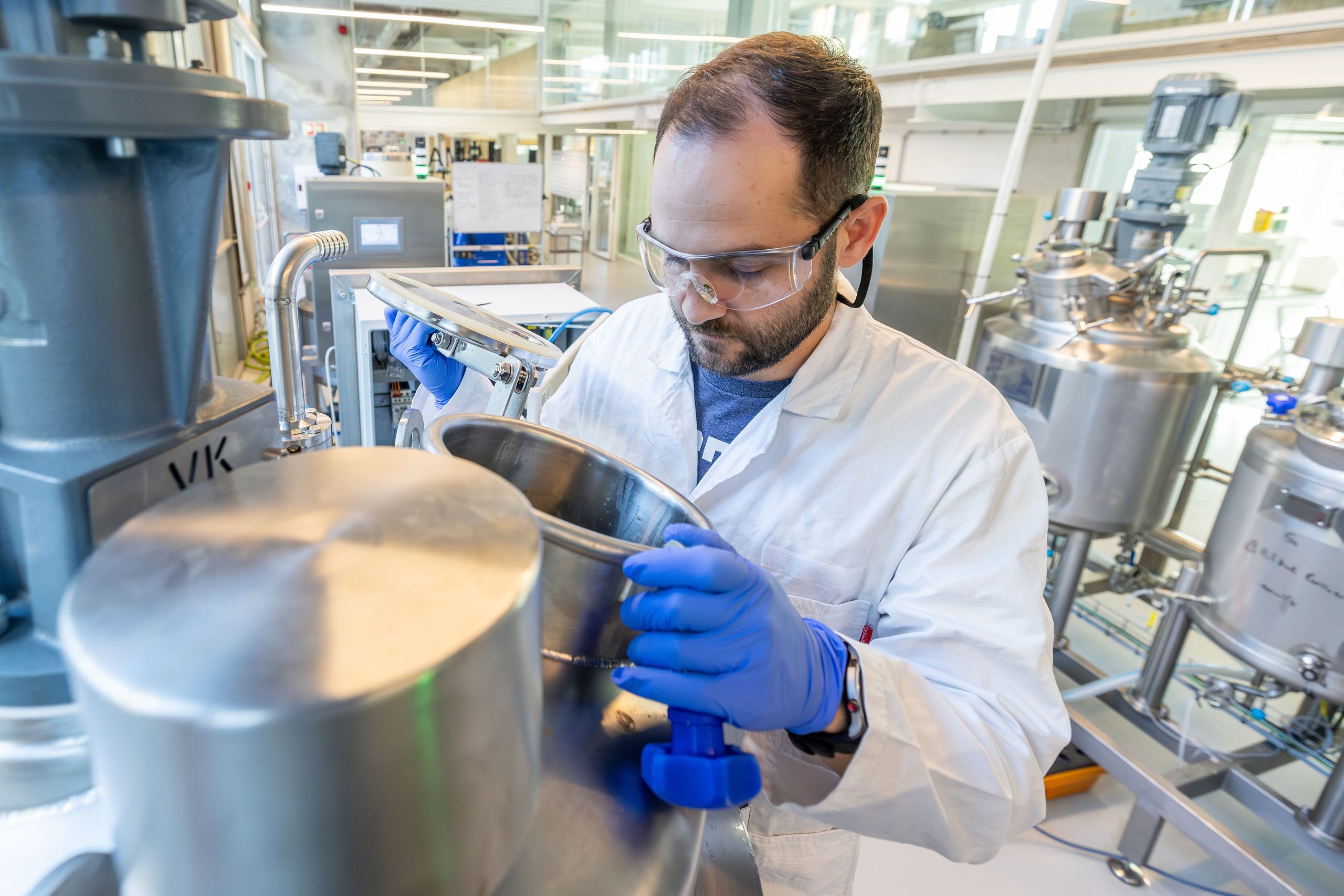

MicroHarvest, an innovator in sustainable microbial protein, has reached a crucial milestone by successfully scaling its production to 10 tons per day in a single vessel—marking a ten-fold increase from its previous capacity. This achievement showcases MicroHarvest’s ability to meet commercial-scale demand, with plans underway for a full-scale facility aimed at producing up to 15,000 tons annually by the end of 2026.

The recent trials confirmed that MicroHarvest’s microbial strain and essential process parameters perform consistently even at larger volumes, underscoring the scalability of its technology. Moreover, the trial highlighted the efficiency and resilience of MicroHarvest’s seed train, enabling full-scale production initiation over ten times faster than traditional methods in the food industry.

Consistent and impressive scalability milestones achieved by MicroHarvest in the biotech industry make it an undisputed leader in the novel ingredients space and have emboldened and accelerated the company’s progress towards a first close of its Series B funding efforts.

Katelijne Bekers, CEO of MicroHarvest, said: “Producers of feed and food face high pressure to adopt novel ingredients within 3-5 years, but scaling these ingredients has been a bottleneck for the B2B ingredients market. First trials require hundreds of kilos or even tons of product to test with, followed by consistent, large-scale production in the magnitude of thousands of tons. While many biotechnology startups struggle to scale their production beyond small pilot volumes in the range of a few kilos, we’ve always successfully run pilots with 50-100 kg of product. In addition, we have also found a solution to address the urgent industry need to diversify protein sources at scale now. Our demonstrated process stability at scale put us in a unique position to actually match market demand in 2026.“

MicroHarvest ran its first pilot trial less than 6 months after starting in the lab. Now, barely 3 years later, they are already demonstrating robust production at commercial scale. The success of this new large-scale trial has solidified MicroHarvest’s confidence in the engineering parameters essential for its next production plant, putting the company on track to meet its long-term commercial production goals.

“We see that new demo factories more than often have troubles in their start-up phase, as the process is sensitive to contaminations or to technical perturbations not expected at lab scale. This leads to delays that can take more than a year. In the worst case, they make profitability unachievable as production losses make a considerable dent in good unit economics.” says Jonathan Roberz, COO of MicroHarvest. “Our R&D and Pilot teams focused from the start on minimizing these problems. Our technology minimizes the risk of contamination and focuses on quickly recovering production upon technical problems. Having overcome any remaining technological barriers, MicroHarvest is committed to reaching its kiloton output target.”

MicroHarvest’s microbial fermentation process produces protein with a fraction of the carbon footprint of traditional plant- and animal-based proteins. Using agricultural side-streams as feedstock, MicroHarvest minimizes the need for additional fossil fuels or land, significantly reducing environmental impact. Earlier this year, the startup collaborated with animal-free pet food producer VEGDOG to launch “Pure Bites,” a first-of-its-kind microbial protein dog treat. In addition, validation and application trials in salmon and shrimp are running or planned with several global aqua feed producers involved, covering million metric tons of feed. Looking ahead, the company plans to expand applications in human nutrition, positioning MicroHarvest as a well-rounded player at the forefront of sustainable protein innovation.

With growing demand across nutrition sectors, MicroHarvest is well-positioned to lead the way in sustainable, scalable protein production, contributing to a more resilient and eco-friendly food system.